Hangzhou Zhongtai Industrial Group Co., Ltd. 2017 Fire Drill

Release time:

2017-11-25 14:25

Source:

Related News

Zhongtai Industrial Co., Ltd. First Aid Training

To better serve all company employees, fully ensuring their physical and mental health and personal safety, and further responding to the national policy call. To this end, the company once again organized the workshop managers for first-aid training in November 2017. Through this training, the employees' first-aid skills and safety awareness were further improved. In addition to supplementing relevant theoretical knowledge, this training also focused on the following key areas: 1, Cardiopulmonary Cerebral Resuscitation: that is, first-aid measures taken for respiratory and circulatory arrest, using artificial respiration to replace the patient's spontaneous breathing, and using chest compressions to create temporary artificial circulation and induce the heart's own

The company held "Lean Production" training

On November 28, 2017, the company held its first "Lean Production" training session in the training room on the sixth floor of the office building. An engineer from IKEA served as the lecturer. More than 30 people attended the training, including the company's vice president, department managers, supervisors, workshop directors, planners, and purchasing agents. It is understood that the core of "Lean Production" is to eliminate all ineffective labor and waste. It sets its sights on perfection, ensuring the company's competitive advantage in the market through continuously reducing costs, improving quality, enhancing production flexibility, achieving zero defects and zero inventory, and at the same time, delegating responsibility within the organization.

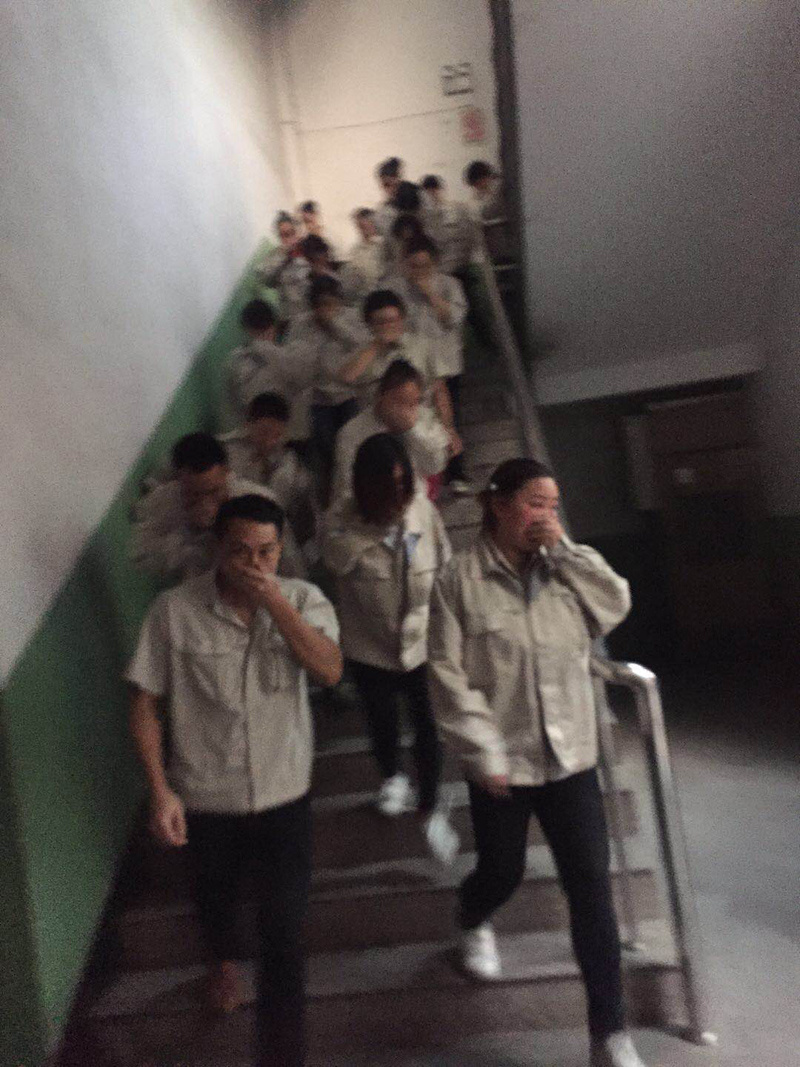

Hangzhou Zhongtai Industrial Group Co., Ltd. 2017 Fire Drill

To earnestly implement the company's fire accident prevention measures, enhance the fire safety awareness of all employees, eliminate fire safety hazards, minimize losses, ensure the safety of material storage, stabilize logistics, work and living order, strengthen the company's fire safety accident emergency work, and enable all employees to understand basic fire knowledge and self-rescue skills, a fire drill was organized and planned on the afternoon of October 27 in conjunction with the Yijiao Safety Supervision Bureau and the Yijiao Fire Brigade. At 5:00 pm on October 27, with the strong support of the company leadership and under the guidance of the Human Resources Department, the Yijiao Safety Supervision Bureau, and the Yijiao Fire Brigade, all

Hangzhou Zhongtai Industrial Group Co., Ltd. is a privately-owned enterprise specializing in the research, development, and production of metal products such as chair trays, five-star bases, washing machine accessories, and lighting accessories. In its early stages, Ni Yongxing, the company's main person in charge, devoted more diligence and hard work than the average person. Today, what makes him most proud is that the company has grown from a small workshop with annual sales of less than a few million to a major taxpayer in the district, and from a small business to one of the top 100 enterprises in the district. These changes did not happen overnight. His long-term engagement in the management of hardware enterprises and foreign trade has instilled in Ni Yongxing a strong sense of competition.

Yiqiao Town establishes the Sino-Thai Education Fund to promote educational development

Recently, the Yiqiao Town Zhongtai Education Incentive Fund, initiated by Hangzhou Zhongtai Industrial Group Co., Ltd. and supported by donations from various sectors of society, was officially established. The fund is supported by an annual donation of 500,000 RMB from Hangzhou Zhongtai Industrial Group Co., Ltd., as well as donations from the community, and aims to support Yiqiao's education sector and promote the long-term development of schools. Hangzhou Zhongtai Industrial Group Co., Ltd. Chairman Ni Yongxing has long been concerned about the development of various undertakings in Yiqiao. Based on the growth of his company, he decided to give back to society by donating 500,000 RMB annually to establish the Yiqiao Town Zhongtai Education Incentive Fund. 2015